Home / Products / WPC Flooring

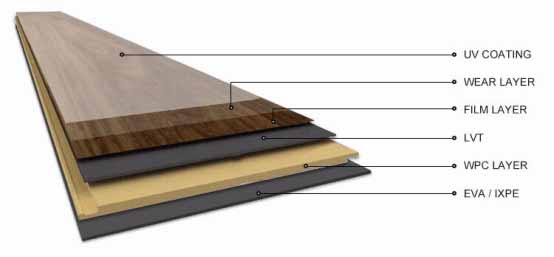

WPC flooring is a collection of Acoustic Vinyl Composite Core click product, which is a new revolution of LVT flooring. It is a perfect alternative to LVT flooring or laminate flooring. It is an engineered flooring product that consists of a LVT top layer, composite core and cork backing with click system. With vinyl on top, it provides a durable and resilient performance; Composite core is an extruded layer which is waterproof with excellent dimensional stability; and cork backing ensures superior sound insulation performance.

Sound-tec

Dual purpose foam underlayment knocks down sound transfer between levels of the home while also providing comfort to live on.

Anti-scratch, pet-free

With fortifier in UM our DIAMOND surface treatment performs better in anti-scratch function.

Abrasion resistance

With fortifier in wear layer, abrasion coefficient of our wear layer is 1500R more than regular wear layer of same thickness from other suppliers.

Anti-bacteria

DIAMOND surface treatment is effective in presenting Grape globular bacteria, Escherichia and fungi, etc.

Wood-plastic composite flooring, also known as WPC, is a new product in the flooring market. Its characteristics make it an excellent hard surface choice for residential and light commercial applications. WPC is a laminate product that provides greater durability, beautiful gloss, and is splash-proof and moisture-proof.

WPC Floor is the true ZERO curling product in the Luxury Vinyl Floor category and it has the best sound insulation performance. This product is very easy to install with little or no tool, and is most suitable for small area applications. You can either simply lay them down, or glue them down for even better performance. It provides extra soft feeling underfoot. Please contact us for more information.

Check the boards before installation to ensure appearance: The factory maintains strict quality control, but the installer is still responsible for ensuring that all boards are acceptable and ready for installation. Do not install the WPC floor in a place where the temperature is higher than 110° F (43°C).

Adjust the WPC Flooring before installation: You must place the WPC horizontally in the room where it will be installed 48 hours before installation. The room temperature and humidity of the installation area should be consistent with the normal perennial living conditions at least one week before the installation of the floor. It is recommended to maintain an optimal room temperature of 70° F/21 C and a humidity range of 35-60%.

| Unit | Result | |

| Total thickness | mm | 5.5-9.0 |

| Thickness of wear layer | mm | 0.3/0.5/0.7 |

| Surface treatment | - | PUR |

| ITEM | STANDARD | UNIT | RESULT |

| Length/Width | EN ISO 24342 | mm | ≤0.10% /≤0.50mm |

| Squareness/Straightness | EN ISO 24342 | mm | ≤0.25mm |

| Total thickness | EN ISO 24346 | mm | ±0.15mm |

| Wear layer | EN ISO 24340 | mm | ±0.05mm |

| Middle/back layer | EN ISO 24340 | mm | ±0.01 mm |

| Total mass per unit area | EN 430 | 一- | +13%/-10% |

| Peeling Strength of layer | EN 431 | — | >50N (50mm) |

| Residual indentation(average) | EN 433 | mm | <0.1 |

| Sound.impact,reduction | EN ISO 717-2 | dB | >4.8 |

| Fire Resistance | EN 13501-1 | — | Bfl-S1 |

| Dimension stability after exposure to heat | EN 434 | % | <0.10 |

| Curling after exposure to heat | EN 434 | mm | <1.0mm |

| Color fastness to light | EN IS0105 B02 | — | grade>6 |

| Loss on heating | JIS A5705 | — | <0.5% |

| Change in length to water absorption | JIS A5705 | mm | <0.20mm |

1. Since WPC will not rot, nor will it be attacked by termites or insects, its service life is often much longer than that of wood.

2. It will not split.

3. It does not need to be painted like wood.

4. As a man-made material, it is dyed so it will not turn gray like natural wood. Due to the presence of wood fibers, when exposed to ultraviolet light for the first time, the product usually has a somewhat tan. This is natural and temporary. The board may turn yellow slightly, but it will fade and stabilize after a few weeks of exposure.

First, the fibers, polymers, and additives are mixed together and heated to form a compound. The composite is then extruded (that is, pushed through the die to form the shape of the WPC decorative board). After cooling, it can be used after finishing.

WPC flooring stands for Wood Plastic Composite. These 100% waterproof engineered luxury vinyl planks and tiles are DIY-friendly, featuring an effortless interlocking system that can be installed over most existing subfloors.

Top vinyl flooring supplier is at your service

If you want to customize floorings for your own brands, or purchase for your projects.please leave a message here, we will send our quotation and arrange the delivery of freesamples as soon as possible.